Jesmonite Powder (AC730)

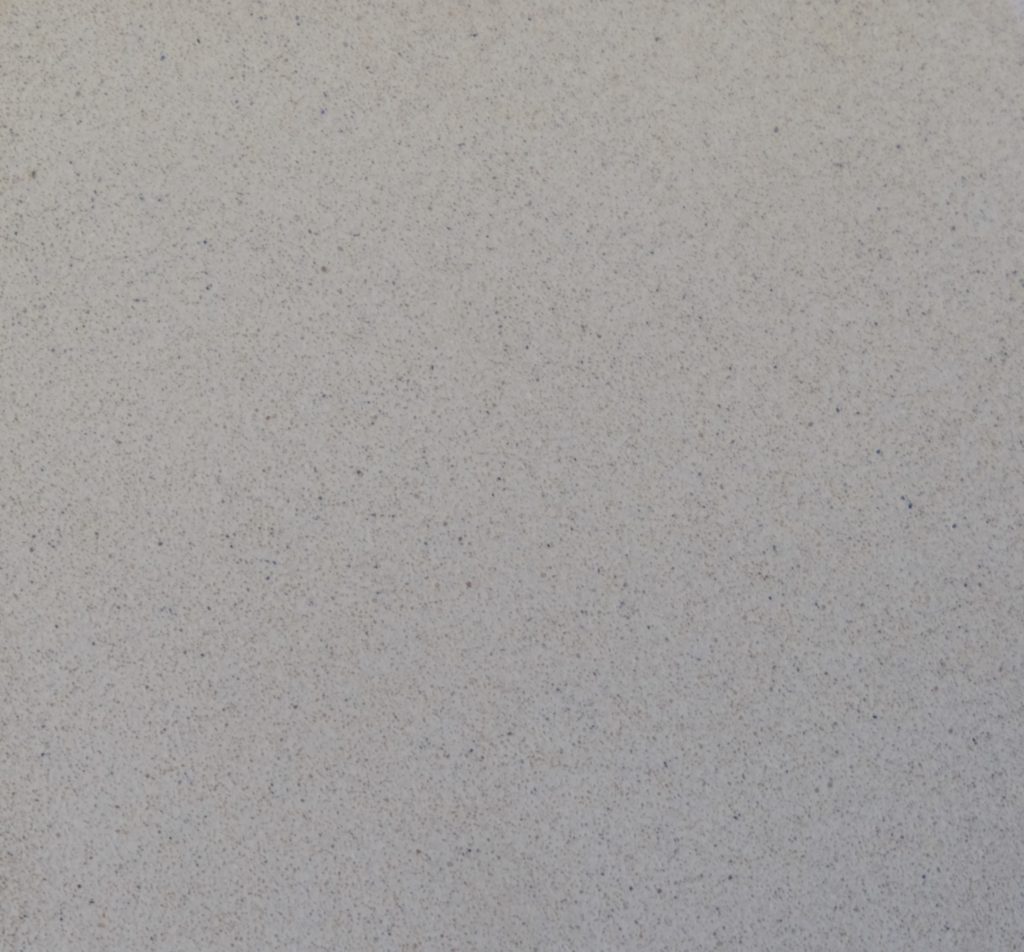

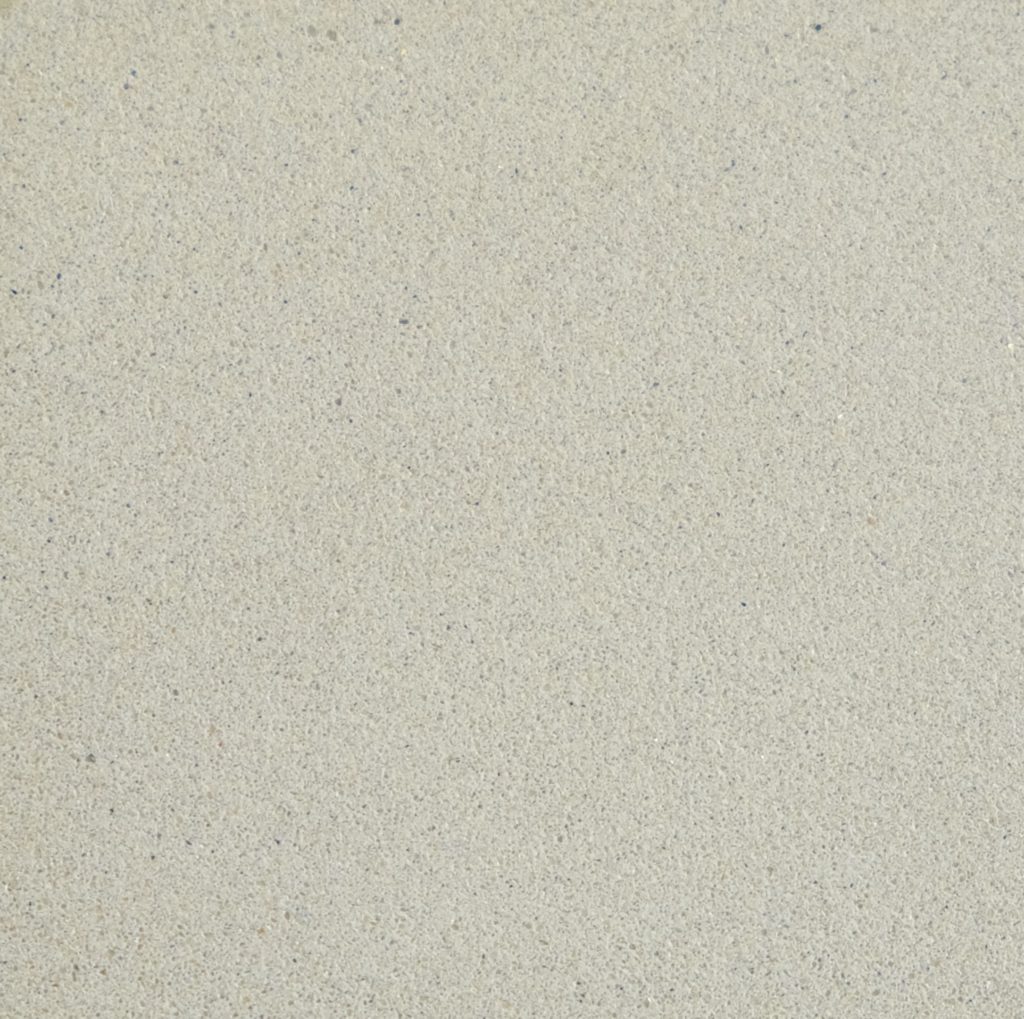

Experiment with multiple stone finishes using one of the 11 different Jesmonite AC730 Base options!

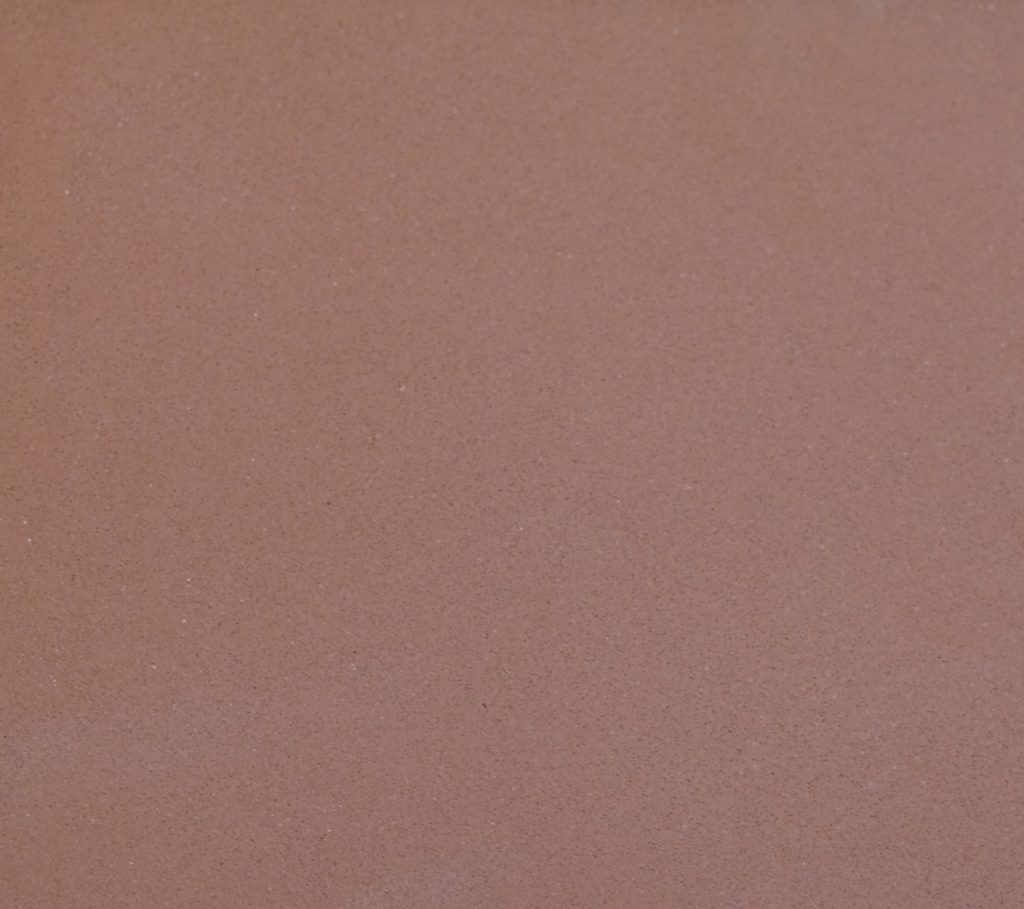

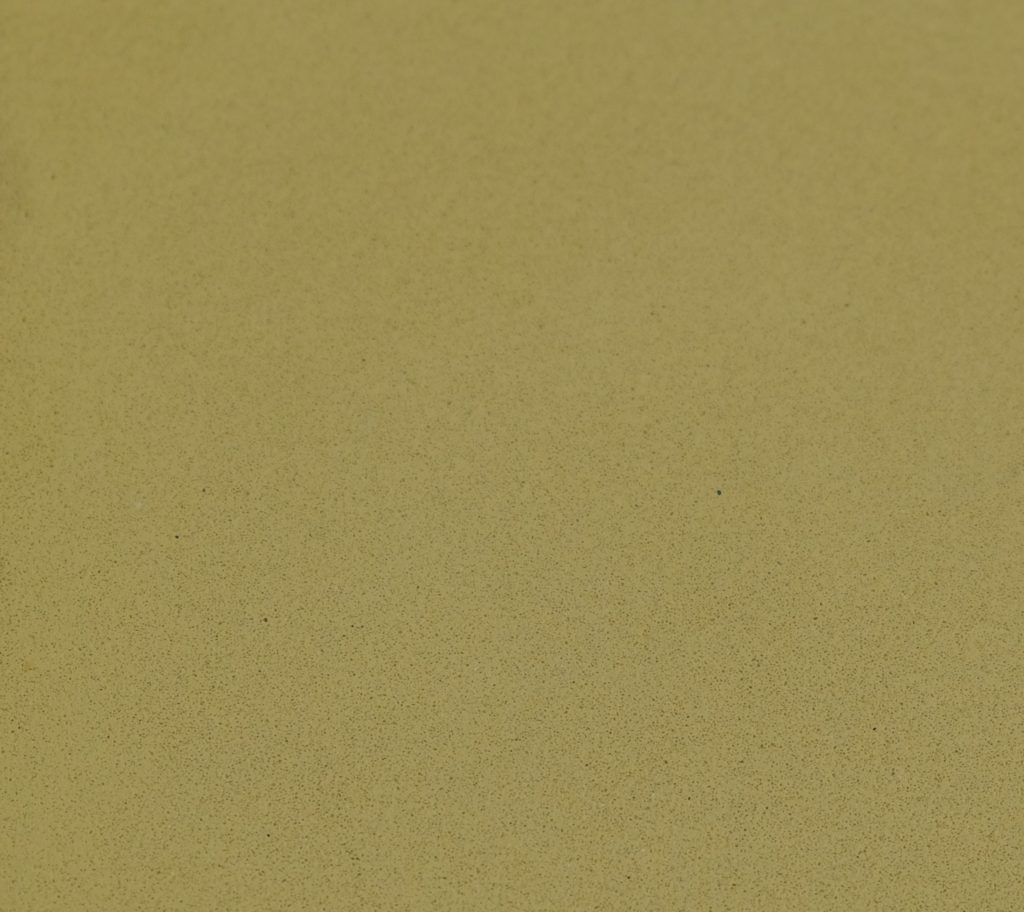

Embrace natural tones with Yellow Sandstone and Old Terracotta or take a walk on the darker side with Charcoal Black or Brick Red. The result is a beautiful, timeless piece that wears well when used outdoors and when exposed to water.

£12.00 - £64.00

Next Day Delivery*

We endeavour to dispatch all order within 24 hours, but please allow 3-5 working days for delivery (due to current global supply chain issues).

Shipping Information

Our shipping costs are worked out by the gross weight of your order delivered to your address. NB: We do not currently ship internationally (UK only).

Enjoy playing around with AC730’s multiple earthy shade options and have fun using Jesmonite’s Acid Etch to reveal the decorative aggregate within the base. Each of the base options are fully compatible with Jesmonite’s AC730 Liquid and AC730 Flex Liquid, so you can create stunning pieces in an array of different shades and textures, just by changing the base you use!

For more information on Jesmonite AC730 and the full kits available, visit our AC730 product page *here*

Jesmonite® is a Registered Trademark

We could talk about Jesmonite all day, but it’s important to note that the above information is based on a mixture of both our experience and Jesmonite’s official guidelines. We can’t guarantee that every piece you make will be perfect, but that’s the beauty of experimentation. If you have any questions about Jesmonite and its suitability for you, please don’t hesitate to get in touch.

For technical data check out our Knowledge Hub.